FlexHammer 1500 Mobile

Unbeaten capacity and flexibility/p>

Want to know more?

Contact us for more information about the FH1500 Mobile

Well known for it’s unbeaten capacity and flexibility

What distinguishes the FH1500 is its ability to achieve very high capacities in relation to the installed power. The hammer mill and engine are optimized for the lowest possible fuel consumption at the highest possible capacity. Your cost per ton when crushing the most common materials will therefore be as low as possible. It’s an efficient mill – for efficient entrepreneurs.

What do our customers think about the FH1500?

Our customers often handle large amounts of waste and their previous crushers lacked the capacity to meet their goals.

Typical materials that the mobile FH1500 hammer mill handles are::

- Demolition and reclaimed wood

- pressure-treated wood, sleepers and other types of difficult-to-crush recycled wood fractions.

- treetops and branches, bark, offcuts from industries, household waste,

industrial waste of different kinds, commercial waste, packing materials.

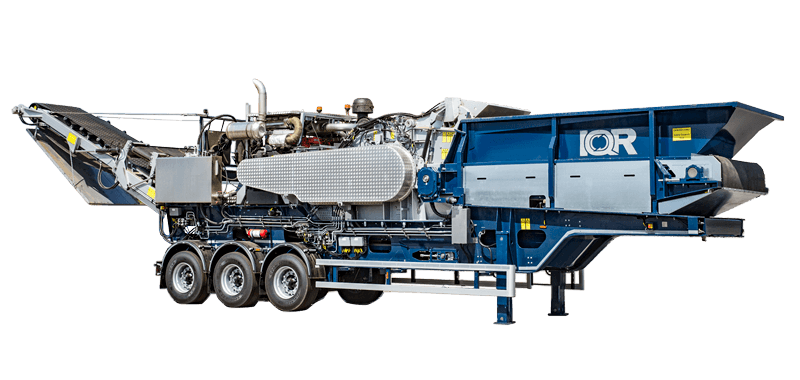

Easy to transport

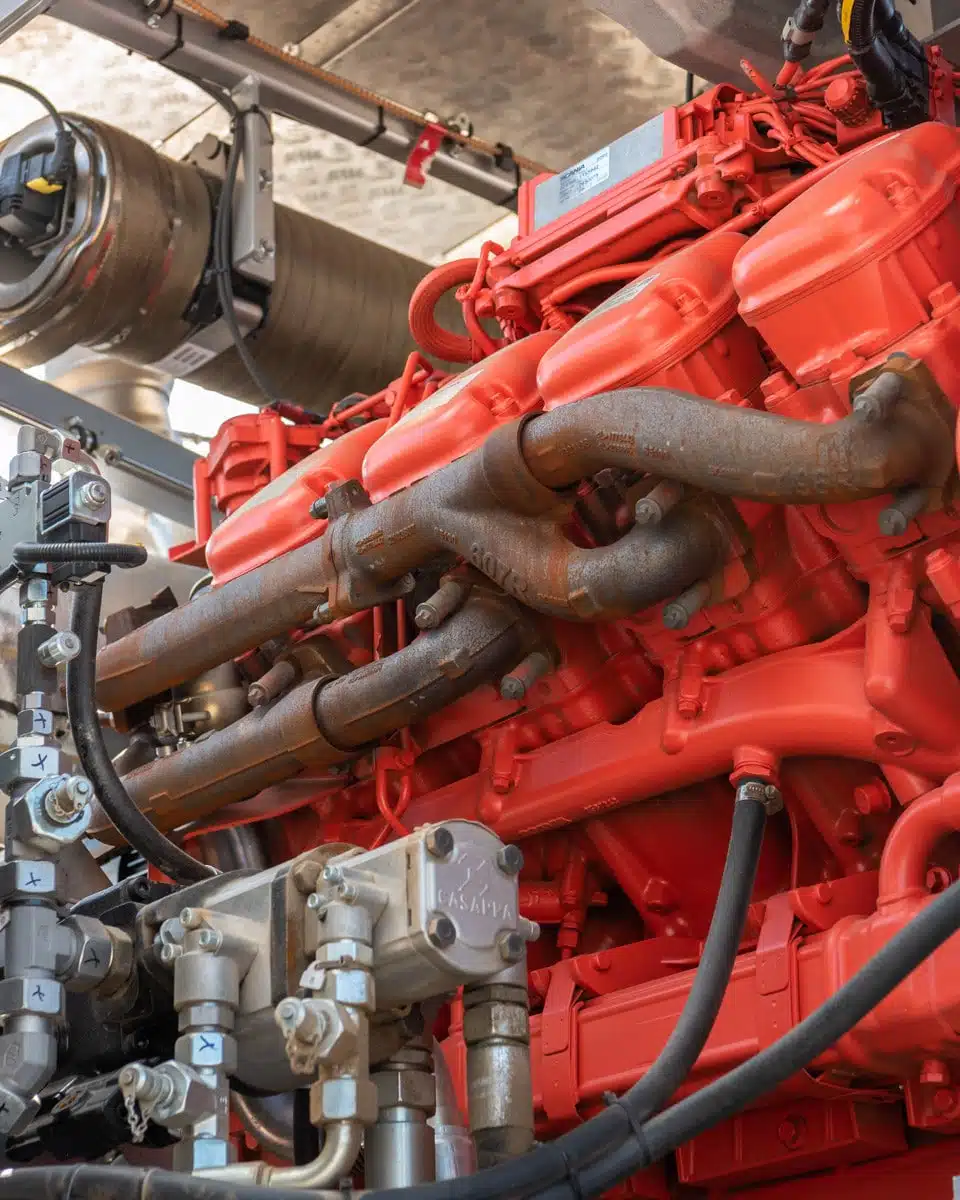

The FlexHammer™ 1500 mobile crusher was developed for easy transportations between sites. The crusher is equipped with a very fuel-efficient engine from Scania. With 770 hp, it has more than enough power. The FH1500 is primarily for you who have large quantities of waste wood deployed in several locations that you need to easily move the crusher between them.

Cost-effective crusher

What distinguishes the FH1500 is its ability to achieve very high capacities in relation to the installed power. The hammer mill and engine are optimized for the lowest possible fuel consumption at the highest possible capacity. Your cost per ton when crushing the most common materials will therefore be as low as possible. It’s an efficient mill – for efficient entrepreneurs.

Typical fractions

The FlexHammer™ system is mainly used when you need finished products of about <100 mm by crushing in one step. Most of our customers process materials for recycling or energy recovery.

The hammer mills design allows you to greatly modulate the size of the output material. for the FH1500 mobile crusher are 0-50 mm and 0-100 mm. All fractions in between up to about 250 mm can be achieved.

Options

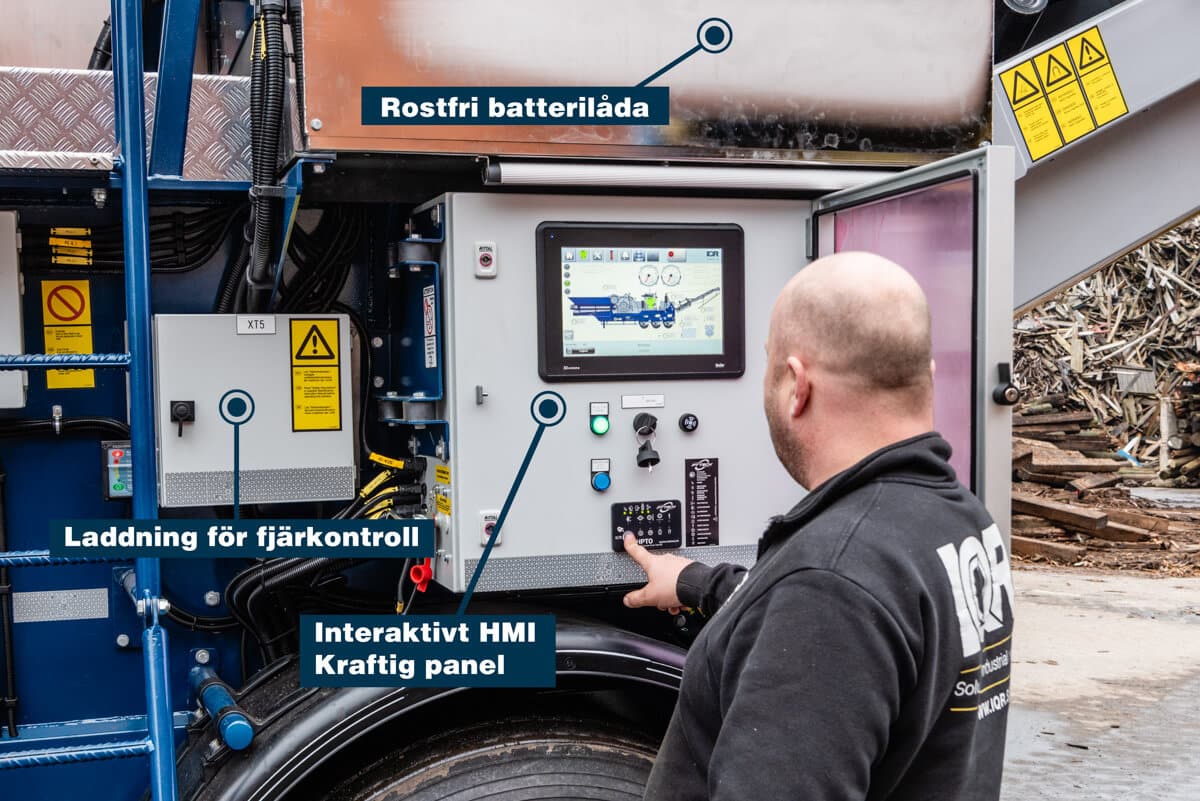

As an extra option, we offer IQR’s Web visualization where you can follow the production online in real time.

You can easily access your information, either if you want to be

connected in your office on a large-screen TV, with a tablet or via mobile phone. The only thing required is a connection, login and browser.

This is the FH1500

Hover your mouse over the red icons to read more about what makes the FH1500 unique.

Data about FH1500 Mobile

| Dimensions | |

|---|---|

| Dimensions transport L/W/H m: | 12,40 (11,5 King-pin) /2,55 / 4,30 m Ready for production within 30 minutes after transport. |

| Total weight: | 35 tons |

| Feeder diameter: | 0,8 m |

| Feeder: | 4,5 m / 1,5m (6m³) |

| Discharge belt width: | 1,2 m |

| Discharge belt – dropping height: | 4,3 m |

| Hammer mill | |

|---|---|

| Rotor weight: | ~4 ton |

| No. of hammers / weight of hammer: | 40 pcs/ 11 kg |

| Rotor diameter / tip to tip: | 1200 mm |

| Rotor speed: | ~880 rpm |

FlexHammer crushers

Are you interested in the mobile chrusher FH1500 Mobile?

Fill in the information below and we will contact you.