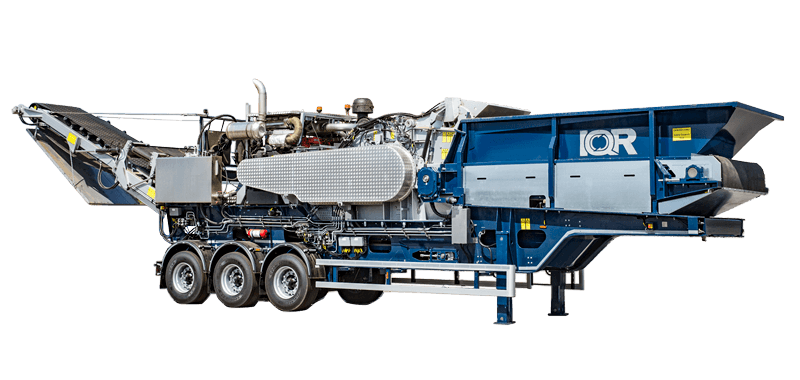

FlexHammer™ Stationary Crusher

- Lower operating costs

- Less and easier maintenance

- See the production in real time online with IQRs Web Visualization

- Possibility of remote service

- Option of longer feeder tables

- FlexReject™ protects the hammer mill from damaging on uncrushable materials

Typical materials that the FlexHammer crusher handles are:

- Wood waste demolition timber, railway sleepers, treetops and branches, bark, offcuts from industries etc.

- Household waste.

- Industrial waste of different kinds.

- Commercial waste, packing materials.

Stationary crushing plants from IQR

IQR manufactures powerful electrically powered stationary crushing plants for all kinds of material in energy recycling and regardless of the desired fraction.

Our customers handle large amounts of household waste, industrial waste, reclaimed wood, sleepers, telephone poles treetops and branches. Other types of waste are also handled where metal separation, screening or other treatment is included as a step in the customer’s process.

Our stationary plants are built exclusively with our FlexHammer™ 1500 or FlexHammer™ 1800 with electric motor, usually with an output of 400 kWs. In some applications the FlexHammer can be preceded by a two-shaft shredder from SID.

FH1500 and FH1800

When you choose a stationary FlexHammer™ plant, you have a large inflow of material to your process facility. Electric power is more environmentally friendly compared to a diesel engine and the maintenance of the electric engine is easier.

An advantage of stationary facilities is that there is no space limitation, which simplifies cleaning, maintenance and service. As we can connect the machine to the internet, the possibilities for monitoring and remote service are also possible. A facility from IQR keeps you updated daily with the information you need.

Safety First

All machines from IQR are built to high standards. Not only to ensure longevity but for safety, which is a number one priority. IQR works closely with industry-leading companies that stay up-to-date with the latest security requirements and a dialogue about security with the customer is always the first priority. Safety standards differ from country to country even within the EU. We always make sure to discuss this with our customers and to explain the pros and cons of certain features. Some aspects of what may look safe are not always the safest option for professionals working with the machine and a dialogue is required to work through what works for the particular customer.

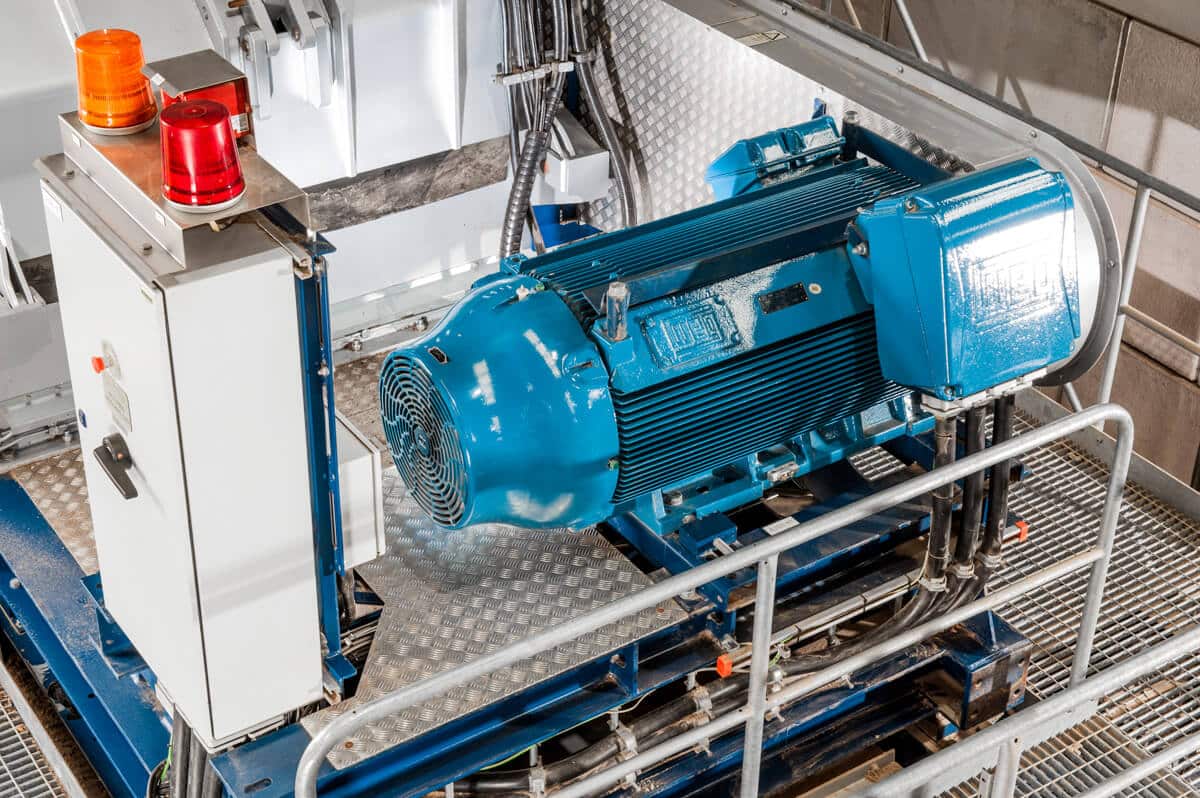

Electric engine

IQR’s stationary crusher uses a powerful industrial electric motor that can handle stress year after year. Electric motors are also much more environmentally friendly. The electric motors are more efficient than diesel motors, which is why kW cannot be compared between the two. You lower your production costs when you use a stationary FlexHammer™ crusher.

It’s an investment worth considering.

Magnets from Elme Magnets

Magnets and metal separation equipment are from Elme Magnets (part of IQR). Depending on the type of machine you choose, magnet size options vary. For stationary crushers, you can choose between electro- and permanent magnets in different sizes.

The advantage of the electromagnet are that it is more powerful and easier to clean, as all the magnetic metals fall off when it is switched off.