Powerful Hammer Mills

Crushes the toughest materials and is not damaged by unbreakable material

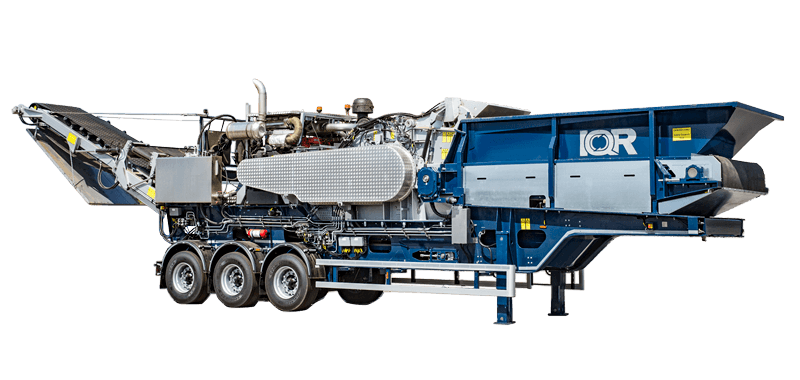

FlexHammer™ Hammer Mill

IQR’s unique hammer mill The FlexHammer™ is designed to crush the toughest materials and is not damaged by unbreakable material. Our customers usually crush waste materials such as household & industrial waste, wood waste, demolition timber treetops, branches and bark. The Flexhammer™ hammer mill is used in both crushing plants and in our mobile crushers.

Common materials that IQR’s hammer mill handles

Reclaimed wood/Reclaimed wood/RT – usually crushed to around 0 – 100 mm but also 0 – 30 mm (40).

Industrial waste (usually paper, wood, plastic and everything in between as materials that should’ve been recycled)

Household waste (waste that, for various reasons, has not decayed or has not been deemed environmentally justifiable to decay)

PVC plastic (usually with large amounts of iron and aluminum) in windows, doors, frames of various kinds. High metal content.

Re-crushing of contaminated metal scrap from wood crushing through a hook shredder or similar in order to obtain a pure metal fraction with a higher value.

Railway sleepers with steel plates, in large quantities

Battery pulverization (alkali/lignite) – with the aim of extracting the metals before destruction of salmiak and other residual products (the crusher becomes a part of the entire plant with filters etc.)

Crushing of waste and biomass

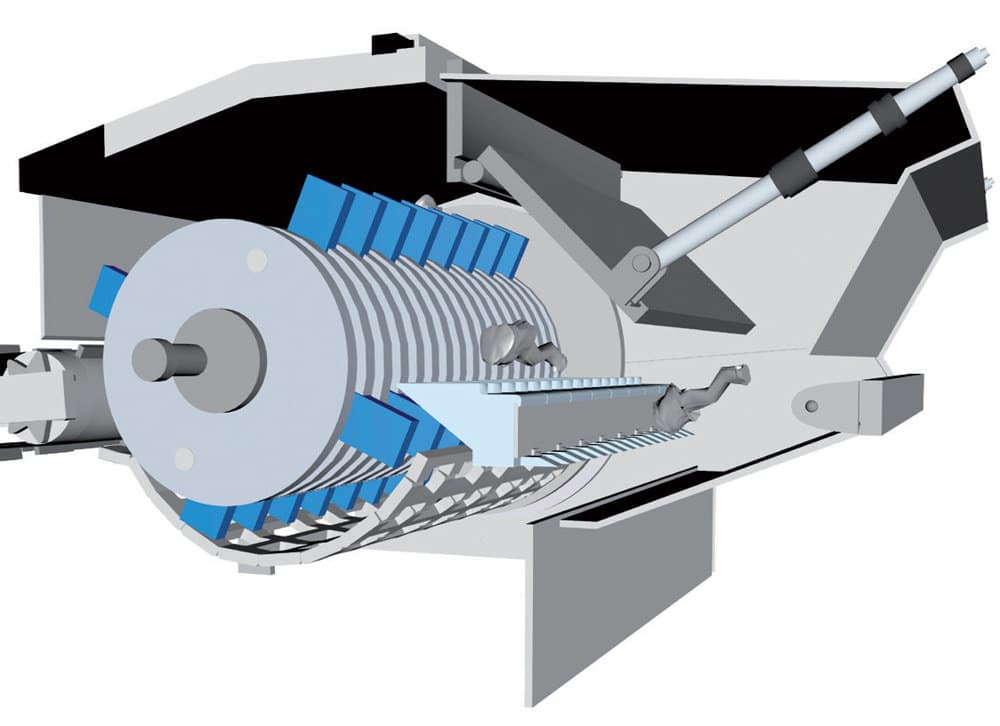

IQR’s Hammer mill has several crushing stages in the same machine.

The crushing starts immediately when material is fed into the machine. The hammers exposes the material to an intensive treatment and material is crushed both by the hammers and material to material.

At the counter knifes the material starts to form its final shape and size. These counter knifes play a large role for the effective treatment of elastic materials such as plastics, textiles, fresh branches, long stripes of bark etc. The counter knifes slows down the material while the hammers tears it apart. The counter knifes are not sensitive to stones or other contamination such as steel, and are also part of the system for release of uncrushable objects by working with the reject door to effectively save the hammermill from damage, should any foreign object enter the mill.

This type of hammermill is very good at securing the desired output fraction. Since the output is most often used as a fuel in for example thermal heating plants it is important to achieve a good size distribution to ensure the good handling, transport, dosing and finally combustion.

Uncrushable material

FlexRejectDoor™

The reject system protects the machine

The IQR crushers (FlexHammerTM) are equipped with a mechanical safety feature, a so-called reject system, which effectively protects the machine from damage.

When uncrushable material, such as large metal pieces or other, is fed into the hammer mill by mistake, the system is activated. The anvils catch the objects before they can cause harm. The hammers then apply pressure to the object, causing the reject door to open. This allows the uncrushable object to be released, and the machine can continue its work without long interruption or damage.

This unique system guarantees high operational reliability and minimizes expensive repairs caused by contaminants in the material flow

This is what the FlexHammer can handle

Our customers regularly send us pictures of uncrushable material that their previous machines couldn’t handle. But with FlexHammer’s unique reject system, that’s no longer a problem. The system protects the machine from damage and blockages, allowing them to handle even the toughest materials without interruption.

Horizontal and vertical feeding

Horizontal feeding with lamella feeder is the most common and most flexible application. Horizontal feeding is necessary for long and bulky material.

Household waste and bark are examples of materials that can be fed vertically. An even material supply to the plant with a correspondingly even feed into the hammer mill is important for high capacity and even quality of the end product